We are interested in the evolution of dynamics during the time-dependent gelation process of LAPONITE®, a synthetic hectorite suspension, using techniques including small and large amplitude oscillatory shear (SAOS and LAOS), the orthogonal superposition (OSP) rheology and probe microrheology.

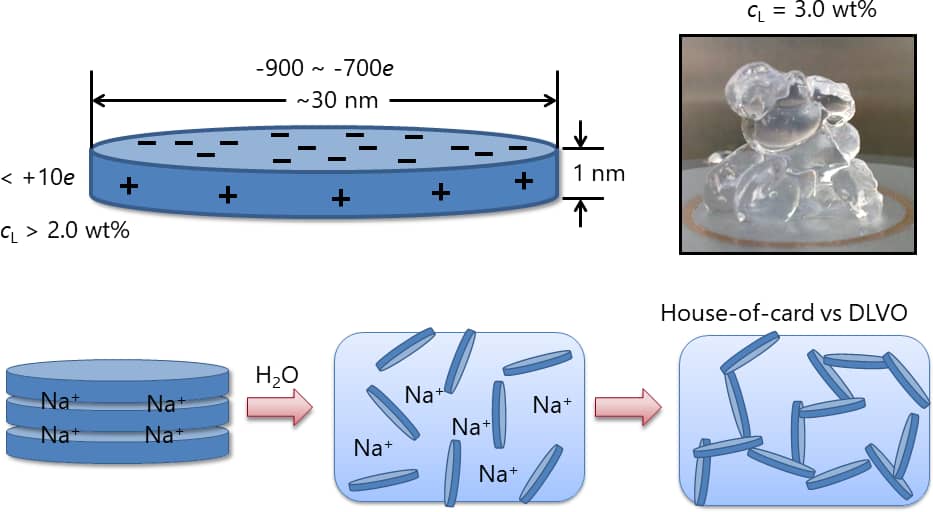

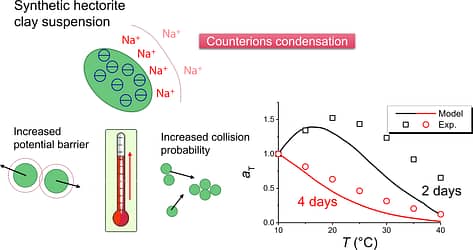

1. Interaction potential

The synthetic clay particles are non-spherical and asymmetrically charged, which is complicated to describe and simulate. We found that the gelation kinetics, which is sensitive to particle interaction potential, can be predicted precisely enough by approximating the particle as negatively charged spheres, but the counterions condensation due to the high surface charge density must be taken into account.[1][2]

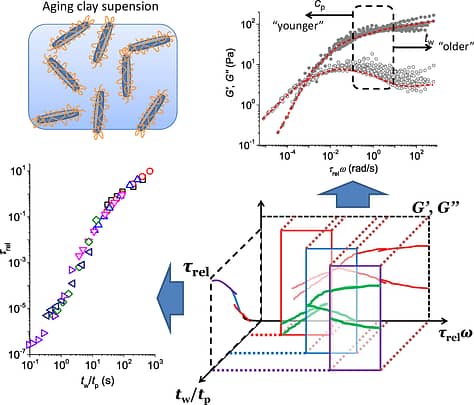

2. Dynamical universality

We found that the evolution of the linear viscoelasticity (LVE) of different systems follows a universal “dynamical spectrum” during the gelation process. This was observed in different modification of particle interaction potential (by adding salts and adsorbed polymers) and temperature.[3][4]

However, the universal spectrum is modified by changing particle concentration, showing a rheological inverse from gel-like to glass-like behavior.[4]

3. Fatigue-like yielding

We found that, under LAOS of constant, not-too-large strain amplitude, the gelled clay suspension withstands the oscillatory shear and responses as an elastic solid for a period of time, before yielding into a viscoelastic fluid. This delayed yielding behavior, considering the cyclic strain condition, is similar to the fatigue failure of metals in that the delay time or number of cycles depends on the strain amplitude by a Coffin-Manson-like relationship, with an exponent, however, much smaller that those of typical metals. Currently we do not know whether it has structural origin or is just an artifact of the homogenization of the flow field. Microrheological investigation is ongoing.

4. “Shear melting”

It is typical to apply a high shear (strain rate or stress) on thixotropic materials (like the clay gels discussed here) before any measurement to erase any deformation history and obtain reproducible initial states. In the glass terminology, the stoppage of the high shear is analogy to a quench from high temperature, thus the phrase shear melting. The strictly defined “quench” of a system, however, actually refers to a jump in the phase/state diagram. For colloidal system the isothermal phase diagram is governed by the concentration of the particle and the interaction potential, although recently a popular jamming diagram does include the coordinate of shear. Can a quench from high shear to a location on the phase diagram equivalent to that from high temperature or low volume fraction to the same location on the phase diagram? This can be check by the effect of quench on the subsequent physical aging behavior, which is already well described by Kovacs’s signatures of aging. To perform the corresponding experiments, we need to measure linear viscoelasticity under shear. This was hard to accomplish until the proposal of orthogonal superposition (OSP) rheology. Using this technique, we found that “shear melting” drive the system to different nonergodic state from quench by other condition under zero shearm, although Kovacs signatures are invariantly followed.

References

- W. Sun, Y. Yang, T. Wang, H. Huang, X. Liu, and Z. Tong, "Effect of adsorbed poly(ethylene glycol) on the gelation evolution of Laponite suspensions: Aging time-polymer concentration superposition", Journal of Colloid and Interface Science, vol. 376, pp. 76-82, 2012. http://dx.doi.org/10.1016/j.jcis.2012.01.064

- R. Shu, W. Sun, X. Liu, and Z. Tong, "Temperature dependence of aging kinetics of hectorite clay suspensions", Journal of Colloid and Interface Science, vol. 444, pp. 132-140, 2015. http://dx.doi.org/10.1016/j.jcis.2014.12.073

- W. Sun, T. Wang, C. Wang, X. Liu, and Z. Tong, "Scaling of the dynamic response of hectorite clay suspensions containing poly(ethylene glycol) along the universal route of aging", Soft Matter, vol. 9, pp. 6263, 2013. http://dx.doi.org/10.1039/C3SM50436K

- C. Liang, W. Sun, T. Wang, X. Liu, and Z. Tong, "Rheological inversion of the universal aging dynamics of hectorite clay suspensions", Colloids and Surfaces A: Physicochemical and Engineering Aspects, vol. 490, pp. 300-306, 2016. http://dx.doi.org/10.1016/j.colsurfa.2015.11.048